Gaffers tape, which is also referred to as gaffer tape, is a form of adhesive tape that has numerous uses. Gaffers tape can be purchased in rolls that come in varying lengths as well as widths. The traditional color of this tape is a matte black but you can find them in several other colors such as blue, white, burgundy, gray, fluorescent pink and so on.

Gaffers tape, which is also referred to as gaffer tape, is a form of adhesive tape that has numerous uses. Gaffers tape can be purchased in rolls that come in varying lengths as well as widths. The traditional color of this tape is a matte black but you can find them in several other colors such as blue, white, burgundy, gray, fluorescent pink and so on.

Gaffers tape is quite similar to duct tape in the sense that it can be useful in an array of applications. However, unlike duct tape, this tape will not leave any adhesive residue when it is peeled off a surface plus it offers a matte finish.

So, what are some of the numerous uses of gaffers tape?

Mark Positions

A common use for gaffers tape is in positional marking. It is commonly used in the theater industry to mark positions on the surface of the floor that will indicate where props are supposed to go. It is often used in the theater and TV industries to mark actors' starting positions. What’s great about this tape is its durability. It won’t easily wear down due to foot traffic. In addition to marking starting positions, it can also be used to coordinate props since it comes in a wide variety of colors.

Manage Cables

Production studios, and convention halls also use gaffers tape to manage cables. Many cables in one area can prove to be a hazard as people could easily trip over them and have a nasty fall. With this tape the cables can be firmly affixed to the floor thus lowering the chances of any accidents happening. And when it is time to remove the cables and wires the tape will not leave them sticky like a duct tape would.

Bus Seat Repairs

Since this adhesive tape is a vinyl-coated cloth product it pairs nicely when covering tears and rips in vinyl seating like on buses. It comes in wide widths like 3 and 4 inches wide and in colors such as burgundy and dark green which works great for matching common bus seat colors and making repairs.

Book Binding

Gaffers tape is also widely used when binding books since its matte appearance is preferable to the shinny look you would get back with a duct tape. Its cloth backing also makes it very conformable so as to wrap nicely around a book binding. Typically a high tensile strength gaffers with good adhesion is used for book binding applications such as Shurtape Professional Grade (P-672) gaff.

Other Uses

Gaffer tape is not only used for positional marking in the theater industry, it can be used in plenty of other places. For example, it can be used to mark a hazard area, an incline, flights of stairs, and so on. FindTape.com sells gaffers tape in all its varieties.

eebf3eca-d848-4acc-a273-f6eed75d5ce1|15|2.5|27604f05-86ad-47ef-9e05-950bb762570c

There are a great number of people who engage in sports. This is good considering that a passive lifestyle could lead to a large number of health problems. However, one thing that is associated with sports is injuries, and you may need athletic tape. At one point or another you will find that since you have sustained an injury or one of your loved ones is injured. So, what exactly is athletic tape and why should you consider it?

There are a great number of people who engage in sports. This is good considering that a passive lifestyle could lead to a large number of health problems. However, one thing that is associated with sports is injuries, and you may need athletic tape. At one point or another you will find that since you have sustained an injury or one of your loved ones is injured. So, what exactly is athletic tape and why should you consider it?

Athletic tape is a form of bandage that has adhesive qualities. As such, it can be used for a myriad of things. If you have sustained an injury on your wrist or your ankle, the athletic tape can be used to keep the joint in place. It would be pertinent to keep the joint immobile so as to ensure it heals well and in the shortest time possible. Usually, this is done by bandaging the joint with a regular bandage then covering it up with athletic tape, which will hold the bandage in place. However, this colored athletic tape is not only used for injuries.

For people who play sports that require the use of a bat or some other prop, the tape can also come in quite handy. By having this tape around your palms or on the handle of a baseball bat, you increase the amount of grip that you have thus ensuring you can play your sport better. This makes it great for hockey sticks and other sports bats too.

Athletic tape will come in a variety of types. Your choice of this colored athletic tape depend on a variety of things. For instance, what you plan on using it for, the type of support that you want, the levels of comfort that you are seeking as well as the amount of time that you plan on wearing it.

The main difference between athletic tape is whether it is stretchy or non-elastic.

Stretch tape: this tape is generally used to apply pressure to injuries like a compression bandage and to provide support. It is typically coated with a rubber based adhesive which sticks well to surfaces or only to itself if it is a co-adhesive tape. It also allows for flexibility and range of motion.

Non-elastic tape: this tape is used as a pre-wrap before a sports activity. It is made of cotton and as the name suggests, it is not stretchy and provides a more firm support.

No matter what type of athletic tape you decide to use, you can find it at FindTape.com.

4af484bb-4525-4abb-98a2-5e9401dfd23c|25|2.6|27604f05-86ad-47ef-9e05-950bb762570c

The double-sided film tape we typically sell for adhering window insulation film to the interior of windows during the winter season is JVCC DC-4109RS tape. If the film is heavier and you need a tape with a stronger adhesive then JVCC DC-4199CS would be another to look at. These would be the closest double-sided tapes our converter stocks which are similar to 3M's 2145C product for indoor insulator film mounting. As far as these tapes' removability you'd want to test them first on an inconspicuous part of the window frame to make sure it removes as desired. Please also remember the more adhesive the tape you go with the harder it will be to remove in the spring. Also both of these tapes are coated with an acrylic adhesive which provides moisture, UV and temperature resistance; however tapes with acrylic adhesive need a few minutes to an hour for the adhesive bond to set correctly when applying them. See our blog entry on general instructions on applying pressure-sensitive adhesive tape for more detailed instructions. Thank you.

The double-sided film tape we typically sell for adhering window insulation film to the interior of windows during the winter season is JVCC DC-4109RS tape. If the film is heavier and you need a tape with a stronger adhesive then JVCC DC-4199CS would be another to look at. These would be the closest double-sided tapes our converter stocks which are similar to 3M's 2145C product for indoor insulator film mounting. As far as these tapes' removability you'd want to test them first on an inconspicuous part of the window frame to make sure it removes as desired. Please also remember the more adhesive the tape you go with the harder it will be to remove in the spring. Also both of these tapes are coated with an acrylic adhesive which provides moisture, UV and temperature resistance; however tapes with acrylic adhesive need a few minutes to an hour for the adhesive bond to set correctly when applying them. See our blog entry on general instructions on applying pressure-sensitive adhesive tape for more detailed instructions. Thank you.

UPDATE: We also now carry Duck Brand Window Kit Replacement Tape if you are looking for shorter length rolls for both indoor or outdoor window film installations.

9e76daa9-185d-4a5c-a19a-d0c46e25da13|30|2.9|27604f05-86ad-47ef-9e05-950bb762570c

Instructions for Regularly-Wound Tape:

We sometimes get calls from customers saying they may have a defective roll of double-sided tape since the release liner on their roll of tape is reversed and now the tape is on the top of the liner. The answer is that that effect will happen when the liner on a double-sided tape roll is removed from a roll without the tape coming off at the same time (if the tape was on the outside of the roll then it would have stuck to the lathe when it was originally cut or to the box it was shipped in for that matter). When the liner goes one revolution around the roll without tape coming off at the same time it will then seem like the roll is reverse wound. To correct the problem you just need to unwind the tape alone (make sure the liner stays in place while you are unwinding the tape) from the roll and go one full revolution around. Then just cut off the tape after that one revolution and the tape will now seem like it is wound the correct way again.

Instructions for ATG (Reverse Wound) Tape:

We sometimes get calls from customers saying their roll of ATG tape is wound backwards (either at the beginning of the roll or somewhere in the middle of the roll). That effect will happen when the initial leader on an ATG roll (the piece at the beginning of the roll which prevents the adhesive from sticking to the packaging the rolls are sent in) is aggressive so you have to be careful it doesn't take off the first layer of adhesive when it is removed from the roll. Also if the adhesive on an ATG roll sticks to a surface without the liner being wound up at the same you can see that effect. Basically when all the adhesive comes off one full revolution of a roll without the liner being wound up at the same time it will then seem like the roll is wound like a regular roll of double-sided tape instead of a reverse-wound ATG roll. Before you start the procedure below it sometimes helps if you use your finger to press firmly down on the width of the tape as you go one revolution around the roll which will help transfer the adhesive to the correct side. Then to correct the problem you just need to unwind the liner alone (make sure the adhesive stays in place while you are unwinding the liner) from the roll and go one revolution around. Then just cut off the liner after that one revolution and the tape will then seem like it is wound the correct way again.

55d0226c-5fd6-413f-bbfb-b22a1b00a54f|102|2.1|27604f05-86ad-47ef-9e05-950bb762570c

We often receive emails from people who have removed tape or are trying to remove tape which has been on a surface for a long period of time. If the tape has been removed often times they are now trying to get rid of some adhesive residue which was left behind on the surface. The first point to make is that removing adhesive from a surface should be done very carefully. Here are some steps can try:

- One quick test, if only adhesive residue remains behind, would be to try using the adhesive side from another piece of tape like duct tape to pull it off.

- If that doesn't work you can try using solvents; however they should always be tested on an inconspicuous part of the surface first to see if they damage it.

- Goo Gone or WD-40 would be of the weaker variety.

- Try acetone or alcohol or you can try looking for an adhesive remover / citrus cleaner such as Polyken 41 or 3M 08987 which we sell on the site.

- MEK and Toluene are the strongest two and can be found at hardware stores (since they are the strongest greater care needs to be taken when using them).

I hope this helps. Thank you.

87fc61fd-e777-487b-8ae5-059611c858ec|24|2.7|27604f05-86ad-47ef-9e05-950bb762570c

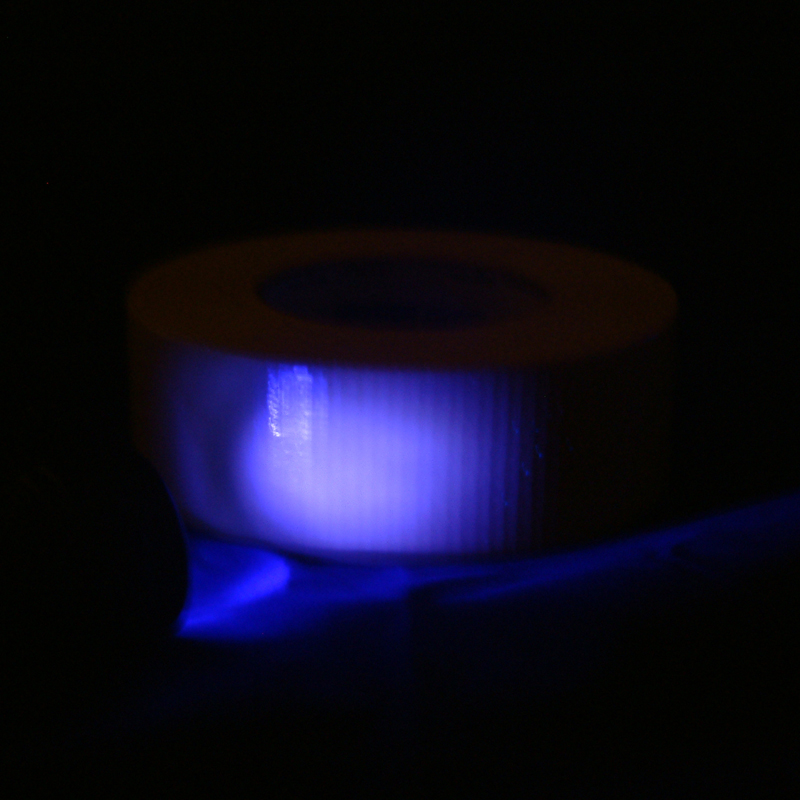

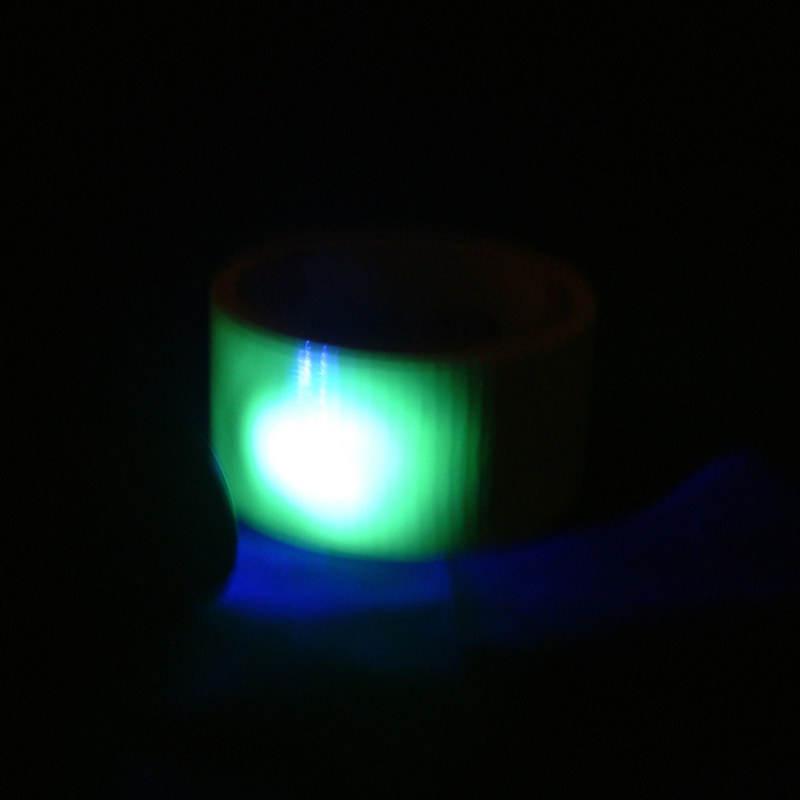

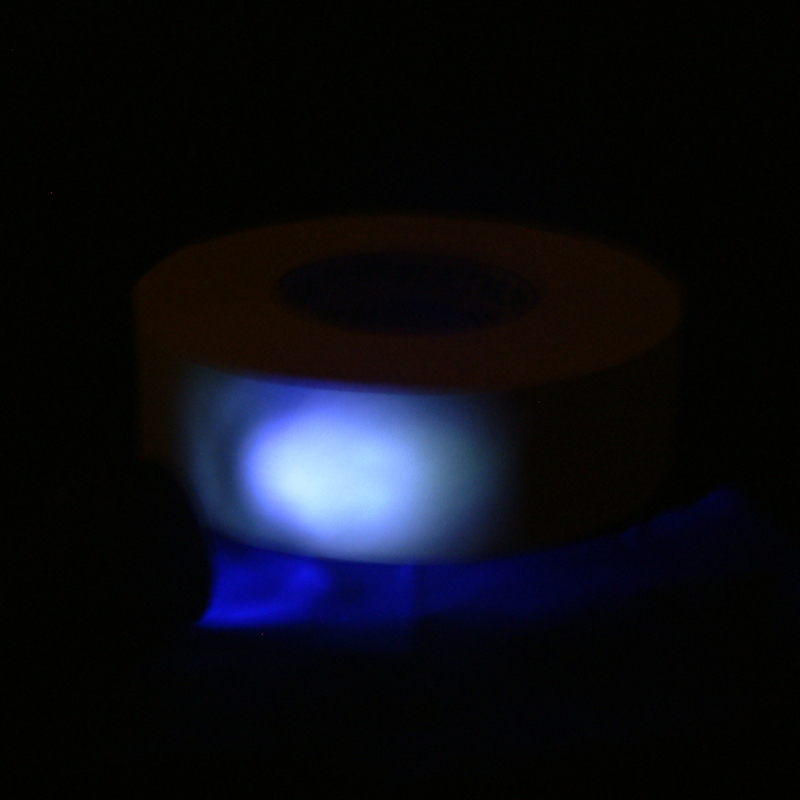

We often get asked how do different fluorescent tapes how up under a blacklight (and what do non-fluorescent tapes look like) so we took some comparison photographs to see. Below are some photos of different rolls of yellow tape and how they showed up for us (these were taken in a light tent with a blue background with a Streamlight 51010 UV Flashlight used as the light source against the rolls):

Regular yellow duct tape

Regular yellow duct tape

(Shurtape PC-600)

Fluorescent yellow duct tape

Fluorescent yellow duct tape

(Shurtape PC-619)

Regular yellow gaffers tape

Regular yellow gaffers tape

(Polyken 510)

Fluorescent yellow gaffers tape

Fluorescent yellow gaffers tape

(Polyken 510-Neon)

*** Our personal observation is that the fluorescent gaffers definitely showed up the best (especially outside of the light tent), but we did get the PC-619 yellow duct tape to fluoresce also. Outside of the light tent the effect on the PC-619 (polyethylene-coated cloth duct) was not as dramatic as it was on the 510-Neon (vinyl-coated cloth gaffers) though.

edc6d007-6166-4e8c-9f17-663799eda067|100|2.2|27604f05-86ad-47ef-9e05-950bb762570c

We're only a retailer, but we work closely with different tape converters who supply us with the products we sell on FindTape.com. We often get asked what exactly does an adhesive tape converter do? Basically a tape converter uses various processes to modify adhesive tape products that they get from tape manufacturers. These processes include slitting, rewinding, die-cutting, printing, laminating, etc. They convert (change) master rolls of tape (similar to large rolls of carpet or newsprint in size) to usable sizes and forms for customers. For instance typically gaffers tape comes in a 56" x 900 yard jumbo roll and then individual rolls are converted from that source material into industry standard sizes such as 48mm x 55m on a rewind slitter that cuts the tape as it pulls it off the source roll and then winds it back up on smaller cardboard cores. Other products may be custom cut on lathes that are more flexible when different widths are required. Tape manufacturers also convert their own tape; but often times it is more economical for a specialized converter to do the work for them (also tape manufacturers typically have very high minimums for rolls cut to non-standard widths).

379e48da-6ca8-43b7-8fa3-6bce7b6be719|13|2.6|27604f05-86ad-47ef-9e05-950bb762570c

The following are some general recommendations or guidelines to follow when applying a pressure-sensitive adhesive tape:

- Make sure the surface you are applying the tape to is completely dry and free of any debris before the tape is applied.

- If any cleaning supplies were used recently on the surface please make sure no residue remains from the cleaning product (if so please use water to remove and then let it dry completely).

- Unwind the tape from the roll (if the tape has a release liner remove it now). During this step be careful not to contaminate the adhesive by touching it at all with your fingers since it will transfer natural oils over to the adhesive side. Also try to immediately bond the tape to the surface without entrapping air between the tape and the surface it is being applied to.

- Use some application pressure (it doesn't have to be that forceful) in order to achieve maximum bond strength. Make sure there is no gapping remaining between the tape and the surface it is being applied to which would allow water to come into contact with the adhesive-side of the tape over time. This would deaden the adhesive and shorten the life span of the tape.

- If the tape has an acrylic adhesive the dwell time the tape needs to be in contact with both surfaces (before it reaches it maximum adhesion) is typically 1 to 24 hours. For best results during this dwell time try to provide some application pressure (e.g. clamps, tape over it, etc.); also if holding an item vertically against a surface try and support the weight if possible.

- For even better adhesion you can also use an adhesion promoter or primer; can see some options at Adhesion Promoter/Primer on FindTape.com.

03da2d22-e2e2-4905-982a-679600987864|15|2.5|27604f05-86ad-47ef-9e05-950bb762570c

While film release liners are great since once you get them started they can be removed very quickly from a roll of tape without the possibility of the liner ripping like a paper release liner may at times do (that's why to cover large areas like a convention center floor the tape needs to come on a film release liner); nonetheless they can sometimes be hard to get started.

The easiest way to remove a release liner is to unwind a section of the tape from the roll and apply that section of tape to the first surface you are bonding to and then let the adhesive set before you try and remove the liner. However, if you need to remove the release liner before the adhesive has set on the first surface here are some tips or guidelines to follow:

- Unwind a short length of tape from the roll.

- Bend a small amount (1/8 to 1/4 inch from the corner) of one of the corners back towards the liner side (so the liner is touching liner) - this will cause the film liner to stretch more than the backing on the tape which will typically result in the liner overhanging the tape by a little bit.

- Then try to drag the tape away from the liner with your thumbnail while using another fingernail to squeeze or pinch the liner in place.

- Once you get enough of the liner removed you will have something to hold on to in order to start pulling the release liner away from the tape.

*** if you have trouble removing the liner with your fingernails you can also try a pair of tweezers, razor blade or utility knife to help separate the release liner from the tape

df91a9a1-9661-46b0-b3b0-fc7ee92e2ea3|20|2.3|27604f05-86ad-47ef-9e05-950bb762570c

When using tape to mark off gym floors you want to be sure you don't use too aggressive a tape so as to ensure the finish/wax of the gymnasium floor does not come up or is damaged when removing the tape. A vinyl tape such as JVCC V-36 colored vinyl tape or a premium vinyl tape such as JVCC V-36P (if you want the tape to adhere a little longer) would be your two best bets. If you'd rather go with a matte finish tape then a low-adhesion gaffers tape such as Scapa 125 would be another one to look at. Thank you.

When using tape to mark off gym floors you want to be sure you don't use too aggressive a tape so as to ensure the finish/wax of the gymnasium floor does not come up or is damaged when removing the tape. A vinyl tape such as JVCC V-36 colored vinyl tape or a premium vinyl tape such as JVCC V-36P (if you want the tape to adhere a little longer) would be your two best bets. If you'd rather go with a matte finish tape then a low-adhesion gaffers tape such as Scapa 125 would be another one to look at. Thank you.

****** UPDATE ******

Shurtape PE-100 FloorMate tape is specifically designed for use on wood floors with water-based finishes and ideal for creating temporary lines and boundaries on gym floor courts. This product leaves no residue, is comformable to curves, more durable than paper tapes and available for immediate shipping in black or white colors.

Shurtape PE-100 FloorMate tape is specifically designed for use on wood floors with water-based finishes and ideal for creating temporary lines and boundaries on gym floor courts. This product leaves no residue, is comformable to curves, more durable than paper tapes and available for immediate shipping in black or white colors.

9a0cf369-8de7-40fb-ae47-660dd22c0206|25|2.9|27604f05-86ad-47ef-9e05-950bb762570c